A Voyage into the Heart of French Technological Excellence

It is impossible to be interested in French HIFI without wanting to find out more about one of its flagship products. Therefore, I want to take you on a journey to the place where Devialet products are made. I ventured out to the Normandy countryside to witness and understand all the steps involved in creating a Devialet—a machine never before been seen in the world of HIFI.

Whether you love them or hate them, it is clear that Devialet’s varied products do not leave anyone indifferent. To understand the company’s commercial decisions, you need to examine its beginnings: from the first, making a Devialet in France meant meeting exigent demands. As a consequence, the company wanted to collaborate closely with an extremely reputable industrial partner who would be able to meet its particularly stringent standards. Indeed, the fact that Devialet chose to work with a firm located not too far from Paris shows that the company wanted to retain a high level of quality control. Based on some initial prototypes, Devialet chose Seprolec, a company located in Vire, Normandy, to build and assembly all its products.

An exceptional industrial resource

When I arrived in the parking lot of the small business park where Seprolec is located, the first thing I noticed was the impressive length of its building. However, I had to go inside to fully appreciate the 5,000 m2 it spans. About 100 people work at the factory; each day, they put together high-tech circuit boards and other electronic products that will be used, notably, by the aerospace or defense industries or to make industrial electronics. Before venturing any further into the building, I had to show identification and don a blue smock and antistatic heel straps.

During the visit, Philippe Larmanger, Seprolec’s industrial manager, was wont to remark, “Here, we specialize in high mix, low volume.” What he meant is that Seprolac fills a somewhat unique industrial niche: it manufactures a low volume of products assembled from many components and it exploits a high level of technological expertise paired with a very flexible production capacity. It makes sense that these two assets seduced Devialet’s management team.

A lengthy and meticulous manufacturing process

Larmanger invited us to check out the long and complex production line. He pointed out that the factory’s impressive length means that production is optimally organized: on one end is the area where the components are stocked and on the other the place where final product assembly takes place. Our visit therefore starts in the enormous components warehouse, which contains 25,000 different parts. A Devialet motherboard alone requires around 1,600 components. Here, all the components, regardless of their form or function, sport labels so that they can be easily traced. A second stocking area is dedicated to housing surface-mounted (SMD) components, which are subject to strict European environmental standards (for example, most components can no longer include lead). “It is also here that we are confronted with our first major challenge, protecting the sensitive components, which must be stored under highly controlled conditions: humidity levels must be between 2 and 5%,” explains Larmanger. It is crucial that these conditions be maintained because these components will be mounted on a circuit board at temperatures of 260 °C (500 °F); at that temperature, humidity levels higher than 5% could have catastrophic consequences. Consequently, moisture-sensitive components are housed in massive, hermetically sealed cabinets.

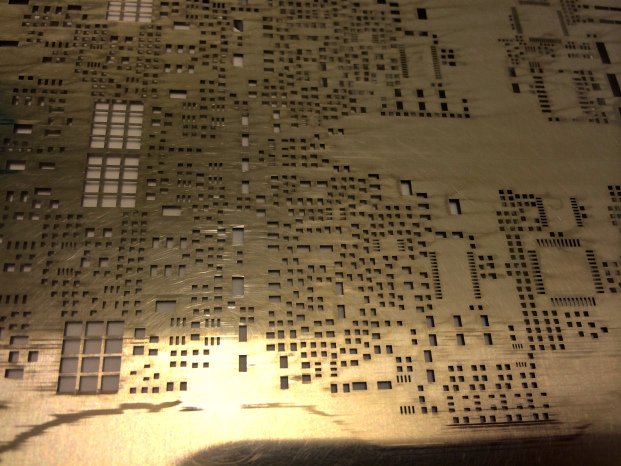

The next step in the process is an essential one: it yields the motherboard, the backbone to which a multitude of components will be attached. The production of the motherboard involves a sort of stencil, a stainless steel mesh about 100 microns thick. An abrasive substance is then applied to etch the board in a very precise way, creating many microstructures onto which the components will be positioned. This positioning process involves large rollers—they form part of an automated assembly line whose job is to arrange the components on the bare motherboard. These machines can lay down 68,000 components an hour.

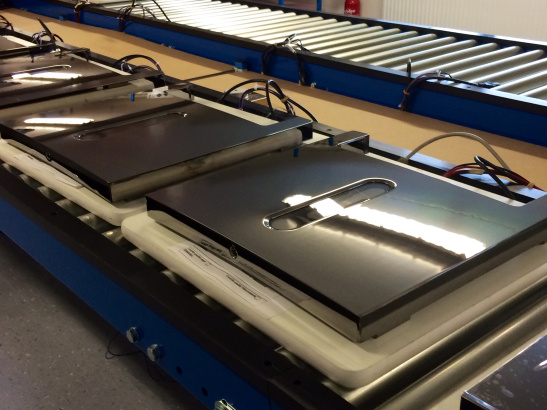

The components, carefully positioned on the motherboard, are then soldered in a single stroke, using a type of wave soldering. This process takes place in a machine, in a nitrogen atmosphere, at a temperature of 260 °C (500 °C). The back of the motherboard will subsequently be extremely carefully bathed in tin. Larmanger underscores several times that all the boards are systematically subject to quality control measures. Although X-ray checks are conducted on only a small subsample, every single board undergoes an automated optical inspection. When the machine finds a problem, human workers will visually examine the suspect board for defects using a microscope. Boards that receive a green light then continue on down the assembly line; the larger components, such as the capacitors, filters, inductors, and battery, will be soldered on by hand.

Devialet’s area

At this stage, the motherboard is almost ready. It will then move on to the part of the factory that is dedicated to Devialet products; this area started off at 30 m2 (323 ft2) in size in 2009, at the beginning of the Devialet adventure, and has since swelled to 300 m2 (3,229 ft2). Within this space are several workstations where assembly is completed and the electronics are programmed. First, the motherboard is mounted in a case, made from aluminum and machined by a supplier in Grenoble. The other 25 steps required to give the case its unique mirror-like look (such as the polishing) are performed by a subcontractor in the northern outskirts of Paris.

Once the motherboard is mounted, all of the connectors can be hooked up. It is important to note that the connectors are assembled straight onto the motherboard to eliminate the presence of small internal cables. During these last, manual steps, the power supply is connected and the LED screen is added, as is the much vaunted remote control (one of the product’s must-have features). The Devialet is now ready to be programmed (a bit like a computer). A suite of programs are installed that regulate the power supply and the ADH amplification system and that manage the remote control system as well as any local or WIFI connections. It is important to point out that the consumer can install system updates via Devialet’s website and the machine’s SD card, a free service that allows the product to continue to improve over time. This extremely novel technological approach defies all the laws of audio systems—updates that increase a machine’s power are absolutely unimaginable for a traditional amplifier.

Before being carefully placed in its packaging, a Devialet must undergo a series of tests and all sorts of quality control checks to verify that it is functioning properly. It takes about three weeks to build a Devialet, from the time the first components are garnered from the warehouse to this final step.

Given its price tag of a little under 5,000 euros, a Devialet remains a luxury item. However, for those who may continue to harbor any doubts, the technological value of this product is indisputable. The well-heeled consumer would be right to question the true added value of a great number of competing products available in this price range (or at much higher prices): since they are conventional amplifiers, they come off as rather antiquated given the adaptive capacities and multiple features of a Devialet.

This article originally appeared in Michel Aublanc’s The State of Sound in France (link below)

Stereo Times Masthead

Publisher/Founder

Clement Perry

Editor

Dave Thomas

Senior Editors

Frank Alles, Mike Girardi, Russell Lichter, Terry London, Moreno Mitchell, Paul Szabady, Bill Wells, Mike Wright, and Stephen Yan,

Current Contributors

David Abramson, Tim Barrall, Dave Allison, Ron Cook, Lewis Dardick, John Hoffman, Dan Secula, Don Shaulis, Greg Simmons, Eric Teh, Greg Voth, Richard Willie, Ed Van Winkle, Rob Dockery, Richard Doran, and Daveed Turek

Site Management Clement Perry

Ad Designer: Martin Perry

Be the first to comment on: A Voyage into the Heart of French Technological Excellence