Viv Lab Rigid Tonearm

Breaking the Mold

What, another tonearm, I hear you exclaim?

The short answer is, yes. But before you flip the page, you really need to read about this tonearm, if nothing else for the fact that it is so very different from anything else on the market. In an age of me-too products where it is virtually impossible to distinguish one hifi component from another apart from physical looks and minute differences in sound quality, the Rigid Float tonearm stands out by boasting clear, unambiguous and logical technical innovations.

These innovations cannot simply be summarized by the name “Rigid Float”, although it’s a good start. The arm itself comes in three models, 7/H, 9/H and 13/H, referring to their respective effective lengths. The suffix “a” in the nomenclature indicates that azimuth adjustment is available via a small screw underneath the armwand. VIV Laboratory Ltd is a boutique audio company based in Yokohama, Japan, and they chose this name for their latest tonearm design to highlight their belief that they have conquered the twin conflicting ideals of any tonearm, that of unrestricted movement, and of rigidity of construction. But in fact, they have conquered quite a few other challenges as well, not least of which is the age old problem of sonic distortion caused by a pivoting tonearm tracking a record that has been cut laterally (by a straight tracking cutting arm). So, without further ado, let’s talk about…

…A NEW ALIGNMENT METHOD

For many years now, the system of offset plus overhang alignment (proposed by H.G. Baerwald in a paper presented at Rochester, New York in May 1941) has been almost universally adopted, often unquestioningly, as the standard bearer for setting up turntable playback rigs. To be sure, the names of J.K. Stevenson and Erik Lofgren are also often mentioned in the same breath, and their contribution to this area is undoubtedly significant. Lofgren, in particular, was the first to point out that the speed of the groove passing the stylus is inversely proportionate to the lateral tracking distortion produced by a tonearm. That is why, inter alia, the closer the stylus gets to the label, the more distortion is usually produced.

So this begs the question: why would anyone want to come up with a brand new alignment system if the one we already have is working so well? More importantly, in an era when an entire generation has never even perhaps saw a vinyl record, let alone heard one, do we really care about a brand new alignment method? Koichiro Akimoto-san, designer of the Rigid Float tonearm, seems to think so. In fact, his name may go down as one of the seminal greats who have contributed greatly to the (antiquated?) art of vinyl playback. His insight is the identification of yet another factor which has hitherto been overlooked by all the alignment experts – that of side force error.

MAY THE (SIDE) FORCE (NOT) BE WITH YOU

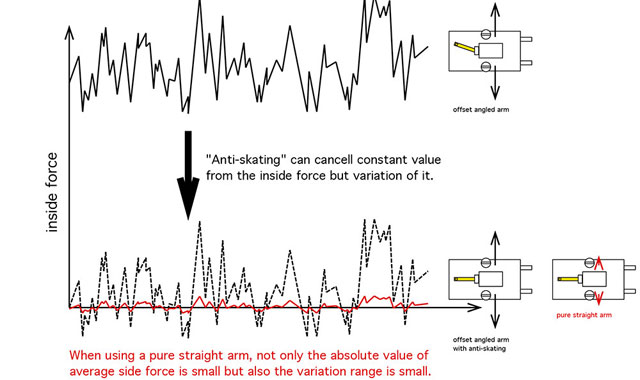

It is well known that, when the tonearm is placed on a revolving record, the tonearm is constantly subject to side forces that try to move the stylus towards the centre of the record. Traditionally seen as no more than an irritant, the main method for correcting this sideways penchant (or “skating”) has been rather unrefined, usually by means of a thread plus counterweight system, or some crude spring systems. The common denominator is a fixed amount of force applied to the tonearm in the opposite direction of this skating, thus the moniker “anti-skating.” Certain vinyl aficionados even eschew anti-skating correction altogether, especially when using high mass arms and/or where the cartridge vertical tracking force exceeds 2 g. Their argument is that the high downforce acts as a sufficient correcting agent to negate the skating effect, and that may very well be true. However, it is still a fixed force in the same way that a spring or counterweight-string combo is a fixed force.

The true value of Akimoto-san’s insight is this: the offset/overhang requirement of Baerwald alignment contributes an inordinate amount of side force to act on a cartridge, causing much more playback distortion than should be accepted. Furthermore, it not only varies according to the groove modulation at any particular moment in time, but also on the tracking error angle. Side force error has two major distortion repercussions: one, distortion caused by diversion of tracking force to one side wall of the groove, and two, distortion caused by such side force on the magnet assembly within the cartridge. Much ink has been spilt over – and man-hours spent on – the importance of holding everything constant while the only thing that moves is the stylus and coil, faithfully transmitting ONLY groove modulations (aka the music signal) to the magnetic circuit within the cartridge body which in turn translates these mechanical movements into an electrical signal. But even in the strictest externally-controlled environment, if a cartridge’s internal magnet assembly moves about uncontrollably, that would negate a lot of the good done elsewhere.

Designer Akimoto-san’s primary argument is this: the offset angle added by Baerwald to almost all tonearms today is fundamentally flawed in that it magnifies side-force variations to an unacceptable level. Let’s use some elementary vector force mathematics to look at this in a bit more detail.

Side force at any particular tonearm position is given by the formula

µW*tan(α+?), where

µ is the friction coefficient between the stylus and groove,

W is the stylus tracking force (or VTF)

α is the tracking error angle and

? is the offset angle

The ideal situation is where µW, representing the total friction force of the stylus, does not favour either wall of a groove. This would meana side force of 0; in other words, the formula tan (α+?) should give a null value. Any other value given by tan (α+?) will mean that some part of the total stylus friction force is vectored towards the wall of the groove closer to the label (or the left wall if you are looking at a stylus head-on).

Baerwald alignment advocates aligning a 25° (24.63° to be exact) offset tonearm to achieve 3 maxima and 2 minima, points where the lateral tracking error (LTE) is the highest and zero respectively. At the highest point of LTE, Baerwald calculations give a tracking angle error of 1.5° (whether the angle is positive or negative does not matter, LTED is the same).

At the point of minimum tracking error angle (α=0) the side force will be: tan (24.63) which is 0.45846925. At the maximum tracking error angle (α=1.5°) the side force is tan (24.63+1.5) which yields 0.49054437. This means that almost exactly half of the total stylus friction force is given over to pushing against the side wall without any anti-skating correction. Anti-skating is the brute use of force to cancel off the effect of a non-zero tan (α+?), which is neither elegant nor ideal. It’s like this: imagine a car in one of its gears (we don’t know which gear and that changes every second) and wants to move forward; to make it stay still, we have two choices; use a fixed force on a rope to pull it backwards, or shift the gearbox to neutral. The question “which is preferable?” is almost a no-brainer, the former having problems of wear, lagging response times, insufficient or over use of force, & c.

So a straight tonearm with no offset is like shifting the car to neutral gear. Even if we take a worst case scenario of a 10° tracking error angle, tan (10) will still only yield 0.18, which is way better than the best case in an offset arm.

Of course, there is still a residual side-force that acts on the cartridge magnet assembly outside of the one ideal position, when the cantilever is pushed to the side pulling along with it the magnet assembly via the tensioning wire and the rubber damper. As mentioned earlier, such magnet movements magnify distortions on the stylus caused by the same side force. This is where the Miyajima cartridges become such an interesting proposition. Their cartridge may have been developed with a different goal in mind, but one major consequence is the isolation of the magnet from the cantilever due to their proprietary “fixed fulcrum” design, and the repositioned rubber damper. Because of this, there should be much less mechanical influence on the magnet due to cantilever movement. I can imagine that any residual side force on the straight arm using the Akimoto alignment affecting the magnet will be largely cancelled out at most tracking error positions, resulting in a predominantly still magnet assembly across the entire record radius. I have not had an opportunity to use a Miyajima cartridge with the Rigid Float tonearm, but I predict it will be a match made in heaven and I can’t wait to try one.

Having convinced himself of the superiority of non-offset alignment, the next question facing Akimoto-san was, where is the best position for the LTE minima? The simplest thing to do would be to fix it right at the middle of the grooved area which will lead to a minimum of adverse effect either side of the zero error position. Indeed that’s more or less where Akimoto-san has determined with his supplied protractor, which is simply an L-shaped piece of clear plastic, with a spindle access hole at one end of the L, and a tiny pin-hole at the other. The idea is that, with the protractor in place and the stylus tip referenced to the pin-hole, all the user has to do is to move the arm base to where the arm tube coincides in position (or is parallel) with the long-arm of the L protractor. The exact position of the pin-hole, as far as I can determine with my analogue vernier calipers, is about 45 mm from the centre of the spindle hole. On an average record, the distance from the end of the dead wax to run-in groove is about 95 mm. This puts the zero tracking error at close to mid-point, but slightly closer to the label side, presumably to compensate additional distortion caused by slower groove speed. With this alignment, there is in fact an underhang, which varies slightly depending on the length of the arm-tube being used.

Which allows me to segue nicely to the next unique feature of the Rigid Float tonearm – its 7” effective length.This flies in the face of received wisdom that the longer the tonearm, the better it is (ok, no biological jokes please). That may be true in an offset world, but even so, not all tonearm designers of Baerwald persuasion –notably Robert Graham of Graham Engineering – espouse this thinking. At any rate, now that we are freed from the tyranny of Baerwald alignment which is calculated based on a minimum of 8”, Akimoto-san is free to experiment with shorter arm wands that he claims will increase rigidity and reduce unwanted resonances within the tonearm. My own tests seem to bear this claim out. Horizontal resonance is between 8 to 10 Hz, and vertical resonance between 10 to 12 Hz, all well within acceptable ranges. But the most interesting thing was that at its peak, visual wobbling was kept to a bare minimum. If I hadn’t been listening out for tone warbling, I would have been hard-pressed to even tell that the arm was resonating at all. This is in contrast to other tonearms which I have tested that danced like a slab of jelly in mid-flight turbulence. How much of this performance is due to the short arm tube length – and its 3 moveable rubber rings to further enhance damping properties – or due to the floating pivot, is moot because everything on this arm is designed to work in tandem.

Which in turn brings me nicely to the eponymous feature of the Rigid Float tonearm – its unique pivoting mechanism. First off, it is important to realize that the floating pivot mechanism is completely unrelated to the new Akimoto alignment discussed earlier. In other words, if you were to fix an offset headshell to the straight floating arm and align the cartridge using Baerwald, the arm would behave exactly like a normal offset arm.

So what is the oxymoronic “rigid floating mechanism”? Most regular pivoting tonearms make use of a mechanicalfulcrum joint that is fixed in place by way of a gimbaled device, a double pivoted setup, or a single contact unipivot that balances on a needle-point. All of these designs are compromised to a certain extent, not least due to the mechanical coupling between arm and base. Akimoto-san describes it in this way:

“There are…types of bearing pivot, [some] dipped in oil bath (oil damped types) available in the market, but still they require some string or other apparatus to fix fulcrum for arm rotary motion, but RF, thanks to automatic positioning mechanism, requires absolutely nothing to interfere with the force, for cartridge stylus to follow the inward path of the record groove”

Coincidentally, just prior to installing the Rigid Float arm, I was experimenting with a mono pivot Gray Research 108 transcription tonearm that, like the RF, sits in a shallow bath of 600,000 cst fluid. Unlike the Rigid Float though, the 108 arm still sits on a mechanical bearing to secure the rotary motion of the arm, without which it will slide disastrously within the confines of the oil well.

As far as I am able to determine, the end of the Rigid Float tonearm also sits in a partially hidden bath of dark damping oil, the color and consistency of dark soy sauce. Akimoto-san considers the viscosity of the fluid a trade secret, but did reveal that the oil itself is magnetized. He explains that:

“As oil is magnetic liquid, [the] single fulcrum point is positioned as horizontal center spin stem floats in bearing suspension cup, composed by [a] doughnut like bowl shaped magnet, just like [a] round shaped ball isfixed in center of cup.”

Presumably, though, the tonearm wires leading out from the cartridge will still represent some form of mechanical join between the arm-base and the arm itself, despite the absence of a physical-contact pivot. In practice, any vibration or resonance going to the arm through the tonearm wires should be so small as to be negligible, especially given the ministrations of the damping oil. So,at one stroke, this ingenious design effectively isolates the tonearm from floor- or support-borne vibrations, keeps bearing chatter to a bare minimum and minimizes problems caused by mechanical friction forces or alignment issues at the fulcrum.

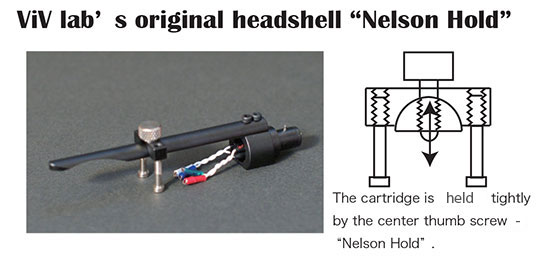

Wait, that’s not all! For the price of a single tonearm, you will also get the uniquely-designed headshell, called the “Nelson Hold”, which is internally wired with 4 nines silver wire, rhodium plated to minimize oxidation effects.

For those non-wrestling fans, we have included a picture of the Double or Full Nelson which will give you a very clear idea of how the cartridge works. Note: guy in pain and long tights = cartridge.

This is a beautifully executed piece of aluminum with a front finger lift as opposed to the more common side lift. I happen to love this sleek form-follows-function design; it looks like some kind of hi-tech weapon. But I can imagine stubby-fingered audiophiles may find the arm lift rather impractical to use. A cross-section of the headshell is shown in the figure above (right).

As can be seen from the cross view, two side screws hold up the cartridge from below, and a centre screw from the top is rotated downwards to press upon the top surface of the cartridge, in the same way the top wrestler immobilizes the other chap down by pulling up his armpits and pressing his head and neck down. This is the essence of the Nelson Hold and is meant to pin the cartridge magnetic circuit tightly in position. Now we can finally see how the pieces in Akimoto-san’s design come together to form a whole picture. Used in conjunction with each other – the straight alignment, the rigid arm-tube, floating oil pivot, and Nelson Hold cartridge – everything works together in a harmonious relationship towards a common goal. There is only one caveat to keep in mind, which I will go into just a little later below.

TESTING, SETUP & USE

Due to its non-mechanically grounded nature, the reviewed RF 7/Ha tonearm was easy to set up. Unlike tonearms that are fixed to a plinth or armboard, the RF simply requires you to move the tone arm base around until you find the right spot where the armtube is parallel or coincides with the protractor. The armbase– which according to the designer is made of brass – is heavy enough to remain immobile once you have determined the correct placement for it, even with relatively beefy interconnects attached to the RCA outputs from the arm itself. VTA is adjusted by releasing a knurled screw at the side of the armbase and lifting or lowering the entire floating pivot assembly (magnetic fluid and all) as the case may be. As this is not exactly a featherweight device, only using a single screw to hold up the entire rig proves to be a flawed idea. There were a few frustrating occasions when, with the VTA beautifully dialed in, I was changing phono cables or trying to remove the headshell, and my fingers inadvertently caused the pivot rig to loosen and drop back onto the base. Once, the heart-stopping drop even caused some magnetic fluid to spill out of its bath – not a pretty sight. An extra screw on the opposite side of the arm pillarto secure VTA would be a sufficient solution. My advice is to tighten the setting screw as much as you can, but there is no need to overcompensate and resort to using spanners or the like. As finger-tight as you can, and taking care when doing anything to and around the ‘arm, should in most cases be good enough.

Throughout the review period, I used two different MC cartridges, at two different ends of the price spectrum. The first cartridge is the Miyabi 47 moving coil which was designed specially for the Japanese boutique company 47 Labs by legendary cartridge maven Haruo Takeda. The second cartridge is another Japanese legend, this time the Denon 103R but modified to reside within an ebony tonewood body. I justify using a modified cartridge in this review as I believe modifying the 103 is a procedure which most users would have tried at least once, some time in their audiophile lives. Reliable information on how to carry out such modifications is also legion on the internet, as are different bodies claiming all kinds of improvements to the stock 103. I will not go into the pros and cons of various bodies, but I did settle on the ebony for the best combination of qualities that I value. Suffice it to say that any surgery done to the 103 will void the manufacturer’s warranty, so be forewarned!

For both cartridges, using the Nelson Hold headshell neat made them sound good, but brought with it a strange sense of disembodiment between different frequency ranges. On a whim, I tried a sliver of carbon fibre between the cartridge and the headshell, and everything snapped back into focus and cohered magnificently. I A-B’d the tonearm with and without the carbon fibre piece using both the Miyabi 47 and the Denon 103R, and without fail preferred the sound with the piece in place. The rest of the review is with the carbon fiber sliver sandwiched in position and with the Nelson’s top screw well and truly tightened down, something I would loathe to do with, say, a $9000 cartridge. Unless that cartridge happens to have a stone body with the words “Koetsu” in calligraphic Kanji, but even then…

One ergonomic feature I really loved about the tonearm is a magnetic holding device when the arm is moved back into resting position. The armwand clicks into the magnetic holder firmly, and you are left in no doubt that it is now secure and will not swing wildly from an accidental knock, thereby merrily lunching your aforementioned multi-thousand dollar pick-up. A further gentle push towards the right fully locks the arm in place, and to release it, you are merely required to apply a careful lateral nudge using the tip of the Nelson Hold headshell towards the record. Fabulous. Makes me wonder why more tonearm manufacturers do not use this kind of magnetic locking device instead of unwieldy arm holders that look for all the world like miniature crutches.

To conduct proper scientific testing of whether the Akimoto alignment actually does produce lower distortion than an offset design is beyond the resources of this particular reviewer. Without an oscilloscope to compare second harmonic distortion, I put the RF tonearm (with a Miyabi 47 cartridge) through anti-skating paces, aka the 300 Hz test tones on the last four cuts of the HFN test LP, recorded at +12 dB, +14 dB, +16 dB and +18 dB respectively. My reasoning is that, if the alignment really works by reducing side force and therefore its attendant distortion effects, these tracks should in theory be reproduced as close to perfectly as is possible. With the last track closest to the label, and at 18 dB no less, it is indeed the most difficult one to track. The Rigid Float arm sailed through the first three tracks without breaking into a sweat. Only the last one produced some buzzing in the left channel, which in itself is already a great result. Following some fine azimuth adjustment, the buzzing was further reduced. I was impressed, as even my current reference, the Graham Engineering Phantom II (still not back in my system after having been upgraded to Supreme status) did not fare as well.

As far as tracking is concerned, the RF’s record has more or less been flawless, except for a few skips at the run-in grooves due more to the low-compliance nature of the Denon cartridge. As for its performance near the dead wax, pinched groove distortion does occasionally rear its head up on certain records, but certainly not as horrendously as other offset tonearms (including 12” ones) and not any worse than the last straight tracker that I owned, a Rabco which was working flawlessly.

LISTENING

There is a trick in audio reviews where a reviewer is unable to hear a certain component under review, and concludes that it is because this component is so neutral that it cannot be heard. So let me get it out of the way right from the beginning: the Rigid Float tonearm is so neutral that it cannot be heard.

This is not to say that I did not hear a change after installing the arm in my system. I did, and the change was immediately recognizable as something indefinable, a “fragrance” almost, that instantly signals a piece of high end equipment. But, as I got over that initial flush of excitement and awe, I entered a different and slightly more puzzling phase of listening with the tonearm. It was during this phase, when I tried to be as critical as I could about the qualities of the tonearm, when I realized it was almost impossible to pin down any particular sound that it may have had.It responds like a chameleon to every change you make to the system, be it a different cartridge, interconnect, or vacuum tube, all of which I have tried during my assessment of the arm.

Some readers may be concerned that, with all the measures put in place to minimize resonances, would the tonearm sound overdamped and lifeless? In fact, I found the opposite to be true. A good example is the first-ever recording of Alban Berg’s Lyric Suite performed by the Ramor Quartet (VoxSTDL 500 530) in which the string instruments not only resonated believably within the recorded acoustic, and the tonearm faithfully rendered all the staccato playing with a tremendous amount of what can best be described as “bounce.” This observation led me to the conclusion that the “bounce” can only be recreated by a system that possesses the sacred trinity of timbral accuracy, microdynamic response, and ambience retrieval. Permit me to expand this a bit more for you.

Some readers may be concerned that, with all the measures put in place to minimize resonances, would the tonearm sound overdamped and lifeless? In fact, I found the opposite to be true. A good example is the first-ever recording of Alban Berg’s Lyric Suite performed by the Ramor Quartet (VoxSTDL 500 530) in which the string instruments not only resonated believably within the recorded acoustic, and the tonearm faithfully rendered all the staccato playing with a tremendous amount of what can best be described as “bounce.” This observation led me to the conclusion that the “bounce” can only be recreated by a system that possesses the sacred trinity of timbral accuracy, microdynamic response, and ambience retrieval. Permit me to expand this a bit more for you.

Timbral accuracy: The RF’s way with rendering accurate instrumental timbres was extraordinary. Not only did it allow me to hear the quality of and difference between violins, it also managed to fool me several times that I was listening to a real instrument. For example, with the ebony Denon 103R playing Berg’s seminal opera “Wozzeck” (CBS Sony 35001-2 boxed set Japanese pressing), a tuba blast just before the famous “I smell blood” line in Act 2 scene IV was so harmonically real and present that I jumped in my seat. The arm also lays bare the difference in recording quality within the same LP; with the Berg Lyric Suite Vox pressing mentioned above, the quartet on the B side (Schoenberg’s late Romantic VerklarteNacht) sounded less vivid and their instruments more screechy. Comparing cello sounds between LPs was supremely easy with the RF, for example, the cello recorded in the Schoenberg piece, while not so engaging, still sounded more intimately mic’d than the one on another record, this time Hindemith’s Sonata No.2 for Cello and Piano (MHS ORH-295) played by Weber Taube and Rudolf Dennemarck respectively. It was as clear as day that the cello here not only had a more distant perspective but was also recorded at a lower level and therefore had less timbral information on tap. The RF’s ability with timbre never made any two records sound like the same instruments were playing, unless of course, they were.

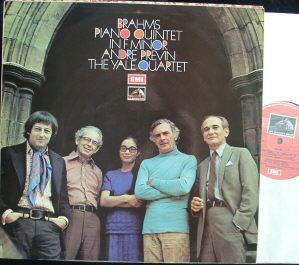

Microdynamics: One of the first LPs I played after the arm was set up and aligned with the excellent Miyabi 47 cartridge was Brahms’ Piano Quintet in F minor Op 34 (EMI ASD-2873) featuring a youngish Andre Previn on the keys. The way the RF reproduced Previn’s finely nuanced playing alone justified its price. Actually no, it doesn’t, but when you are basking in the magnificent presence of the maestro and the redoubtable Yale quartet, the price of the tonearm does momentarily pale into insignificance. It is this very quality that produces the high end “fragrance” to which I alluded earlier in this review.

Microdynamics: One of the first LPs I played after the arm was set up and aligned with the excellent Miyabi 47 cartridge was Brahms’ Piano Quintet in F minor Op 34 (EMI ASD-2873) featuring a youngish Andre Previn on the keys. The way the RF reproduced Previn’s finely nuanced playing alone justified its price. Actually no, it doesn’t, but when you are basking in the magnificent presence of the maestro and the redoubtable Yale quartet, the price of the tonearm does momentarily pale into insignificance. It is this very quality that produces the high end “fragrance” to which I alluded earlier in this review.

But the RF does macrodynamics too, and boy does it ever. One example will suff

One thought on "Viv Lab Rigid Tonearm"

Leave a Reply

Stereo Times Masthead

Publisher/Founder

Clement Perry

Editor

Dave Thomas

Senior Editors

Frank Alles, Mike Girardi, Russell Lichter, Terry London, Moreno Mitchell, Paul Szabady, Bill Wells, Mike Wright, and Stephen Yan,

Current Contributors

David Abramson, Tim Barrall, Dave Allison, Ron Cook, Lewis Dardick, John Hoffman, Dan Secula, Don Shaulis, Greg Simmons, Eric Teh, Greg Voth, Richard Willie, Ed Van Winkle, Rob Dockery, Richard Doron, and Daveed Turek

Site Management Clement Perry

Ad Designer: Martin Perry

Very interesting and interesting handles. It would be nice to try one of these handles on my Lenac GL 75. I think it would be an excellent combination. I take note with respect and if there is any special promotion with discounts feel free to contact me.

Kind regards from Darko from Croatia